Laser Cutting Kerf Explained

In this article, we’ll run through the most important things you need to know about kerf in laser cutting. We’ll explain what the term kerf width refers to, whether or not you need to take kerf into account in design, and what factors affect laser cutting kerf widths.

What is Kerf in Laser Cutting?

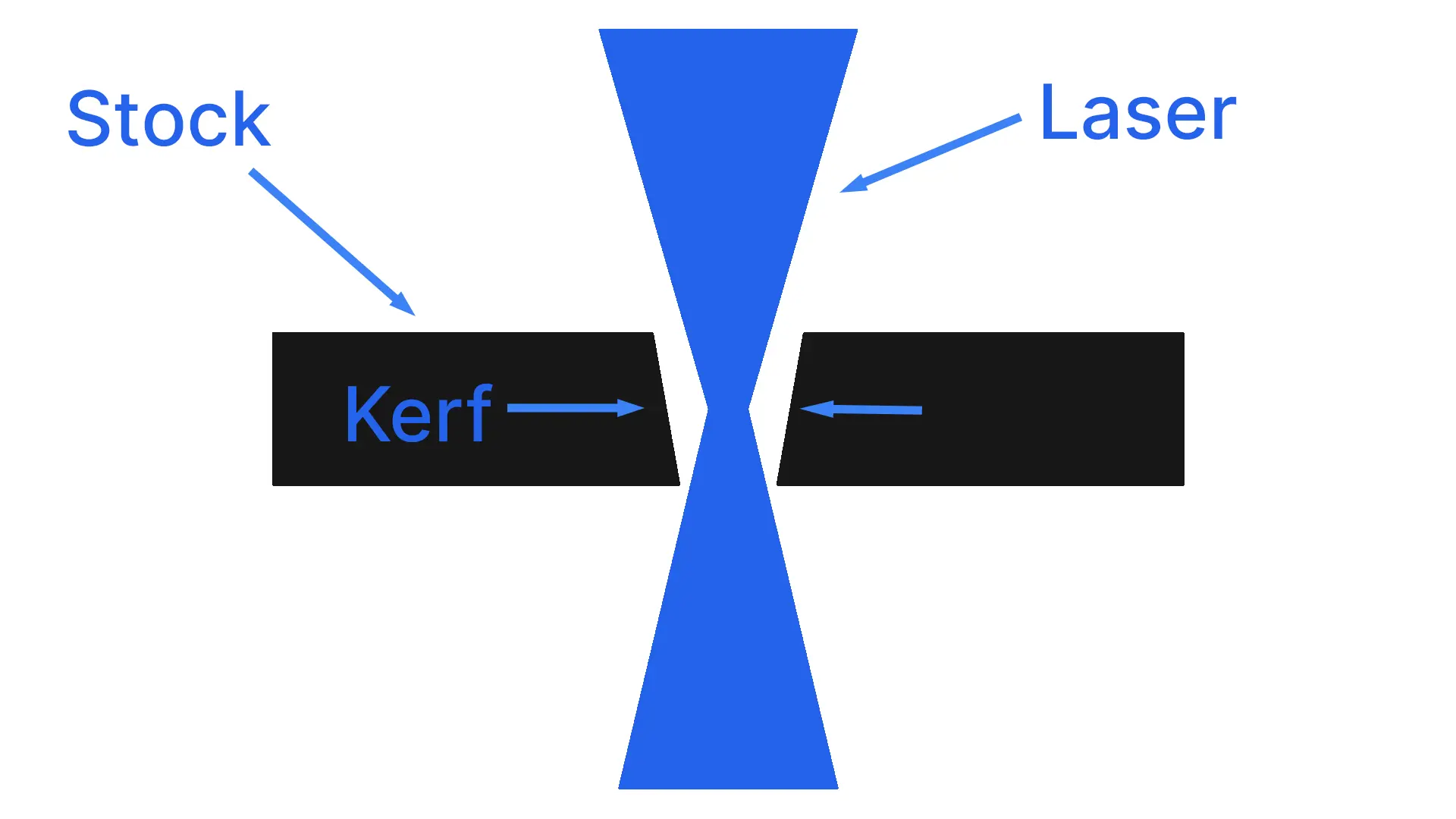

The term “kerf” is used in all forms of cutting in which the cutting device removes material at the incision point. The “kerf width” is the width of material that the device removes as it makes a cut.

Laser cutters burn away material as they cut. In laser cutting, kerf width refers to the width of material that the laser burns away as it cuts.

Kerf is mainly something that needs to be considered in the manufacturing process. On some occasions, however, designs also need to be adjusted to take into account the kerf width of laser cuts.

When Do You Need to Account for Kerf in Design?

Important: You do NOT need to account for kerf width in laser cutting files you send to Fabworks.

On the vast majority of occasions, kerf can be accounted for at the manufacturing stage. The manufacturer can simply calibrate their laser cutter so that it’s offset according to the kerf width that it will make. This leaves a part with the dimensions as specified in the design.

The principle is simple, but expertise is often required. As we’ll discuss shortly, kerf widths differ between laser cutters, between materials being cut, and according to other factors as well. The important point, however, is that designs do not usually need to be altered to account for kerf width.

At Fabworks, we take care of all kerf considerations. Your parts do not need to take the kerf width into account.

Intricate and Detailed Designs

There may be exceptions with parts that have very detailed and intricate designs.

If a design has any areas in which cut lines come very close together, it is possible to encounter problems in achieving the correct dimensions through laser offsetting. What’s more likely to be an issue, however, is problems with warping and fragility that occur as a result of the heat generated in the laser cutting process.

Few parts have geometries small enough for kerf width to be a consideration that needs to be taken in design. We will inform you if this is the case with designs you submit to Fabworks.

For more detailed information look at the Fabworks laser cutting guidelines.

What Factors Affect Kerf Width?

Kerf widths for all types of cutting can vary between .003” and .039” (.080 mm and 1 mm).

There are a number of factors that come into play. The most important factors are:

- The type of laser being used

- The material being cut

he power of the laser being used to make a cut will impact kerf width. Generally speaking, higher power levels result in wider kerf widths, and lower power levels result in narrower kerf widths. As well as this, the focal length and diameter of the laser beam is another important factor impacting kerf width. Different optics can be used to control this.

Other factors in the set up of the laser cutting machine can come into play.

Some of those are:

- The speed of cutting

- The pressure levels of assistive gases

At Fabworks, we use fiber lasers with kerf widths ranging from .005″ - .015″ (.127 mm - .381 mm)* depending on material and stock thickness.

Material Types

Different materials cut with different kerf widths according to their physical characteristics. Generally speaking, softer materials cut with a wider kerf width. That said, dense materials may require high-power lasers, which can cause kerf widths to widen.

Here’s a quick rundown of the main material types:

- Metals - Kerf widths vary between metal types. However, metals generally cut with a narrow kerf width because they are heat resistant.

- Woods - Wood cuts with a wider kerf than metal because it is flammable and less heat resistant.

- Plastics - Plastics are also less heat resistant and less flammable. Plastics with higher melting points will have reduced kerf widths.

- Ceramics - The heat resistance of ceramics means they tend to cut with a narrow kerf width.

Lasers can also be used to cut other materials, including paper and cardboard, fabrics, leather, and composite materials. Kerf widths will vary with other materials. Another thing to be aware of is that if a material has a coating, this may affect kerf width.

At Fabworks, we offer laser cutting with aluminum, mild steel, and stainless steel.

Material Thickness

Thicker materials tend to require more power and a wider laser beam. As a result, kerf widths tend to be wider with thick materials.

Tapering may also be more of an issue with thicker materials. This is when laser cutting leaves cut edges that are tapered rather than exactly perpendicular to the material’s surface. Most materials typically taper .001” (.025 mm) for every .1” (2.54 mm) in thickness.

Fabworks

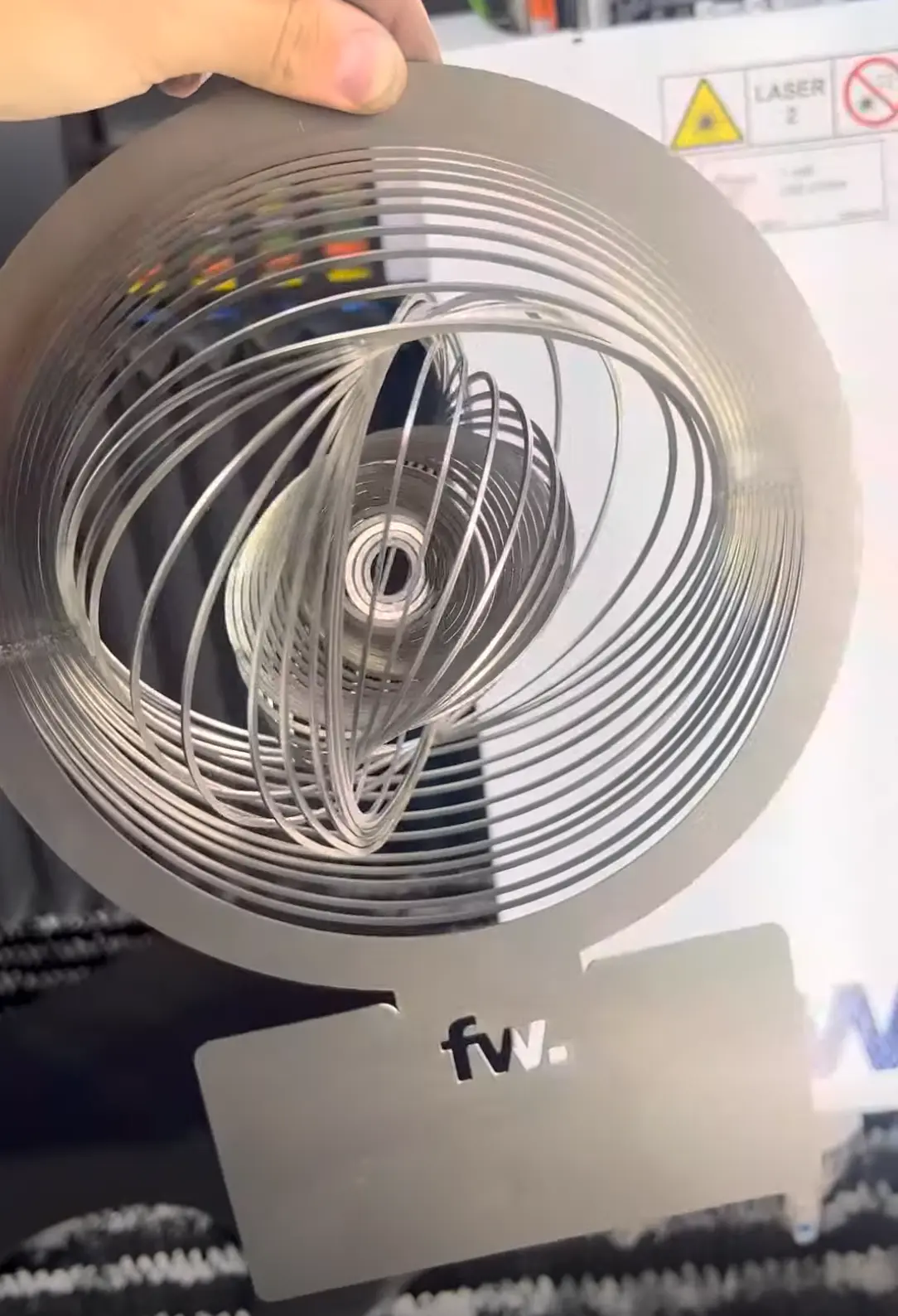

Laser cutting is a cost-effective method of cutting that is suitable for everything from prototypes to large production orders.

Send your CAD designs for laser-cut parts to Fabworks, and we’ll handle all considerations related to kerf width. We’ll also give you an instant quote and deliver high-quality laser-cut parts to you.

How Does Laser Cutting Compare to Waterjet Cutting and Plasma Cutting?

Two cutting methods that might be compared to laser cutting are waterjet cutting and plasma cutting. Both of these methods tend to result in kerf widths that are wider than with laser cutting.

Order Sheet Metal Parts .

Upload your STEP file for an instant laser cutting quote. Quote in seconds, order in minutes, receive parts in days.

or drag and drop

.STEP / .STP up to 25MB

Your file are safe, secure and retain all intellectual rights.