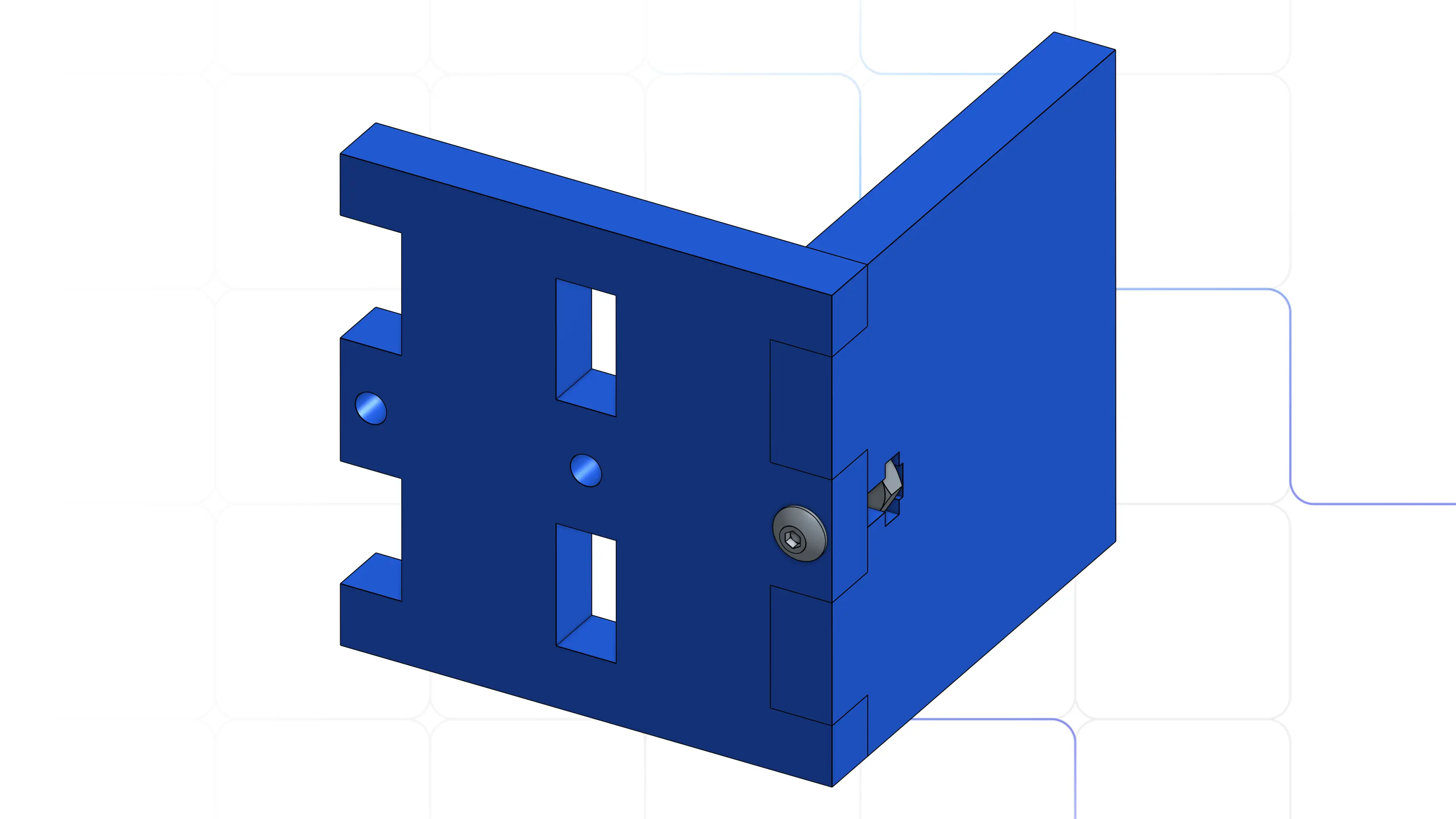

Enhance your parts using Captive Nuts!

There are countless ways to assemble laser cut sheet metal parts together, some requiring requiring expensive tools, or are just impossible in thicker material. By integrating captive nuts into your parts you can super easily attach two parts together at a 90 degree angle. This method of fastening is well suited to thicker materials, since you will have a harder time getting a nut to rest on the edge of a thinner sheet metal. We recommend a material thickness of at least 1/8" to use captive nuts.

What are Captive Nuts?

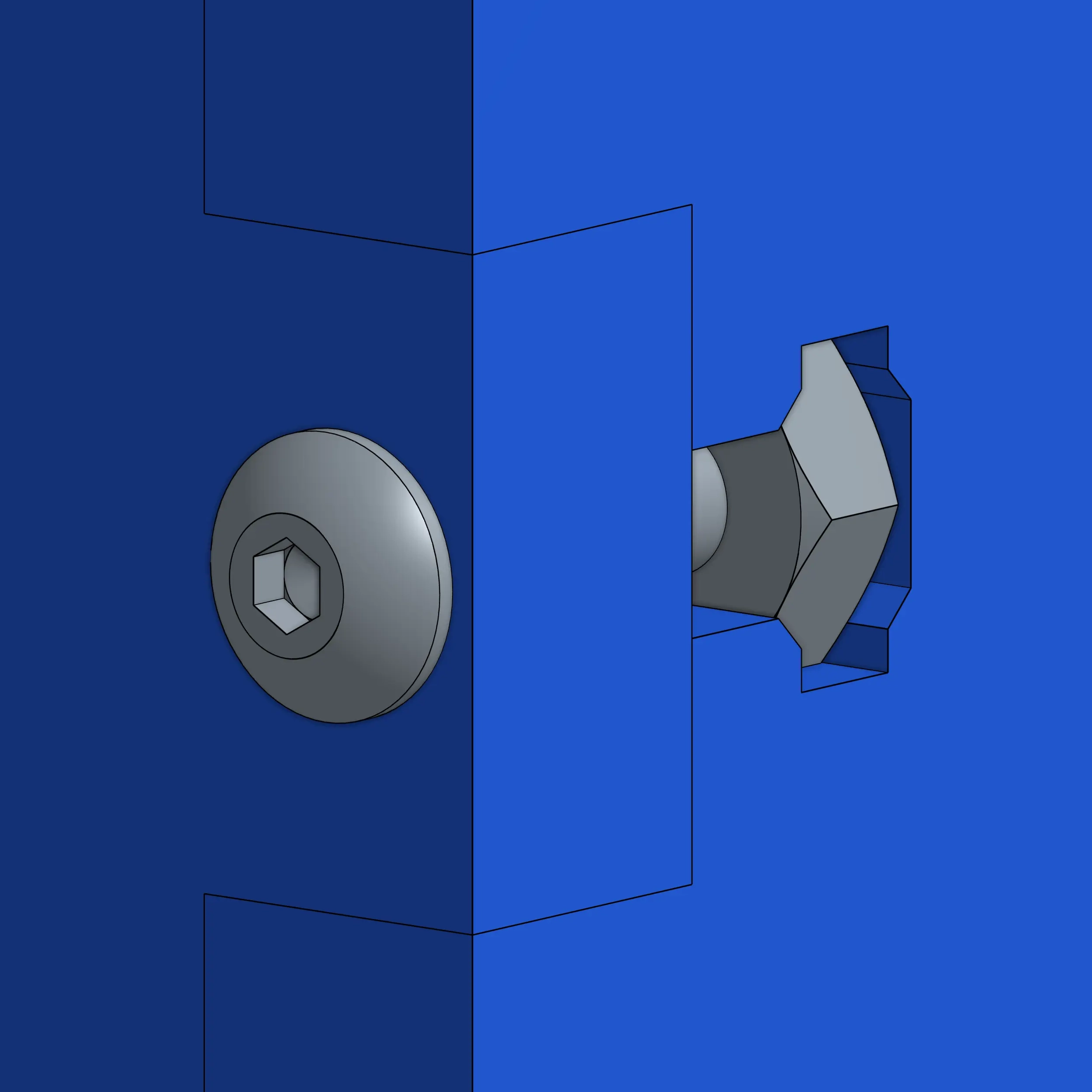

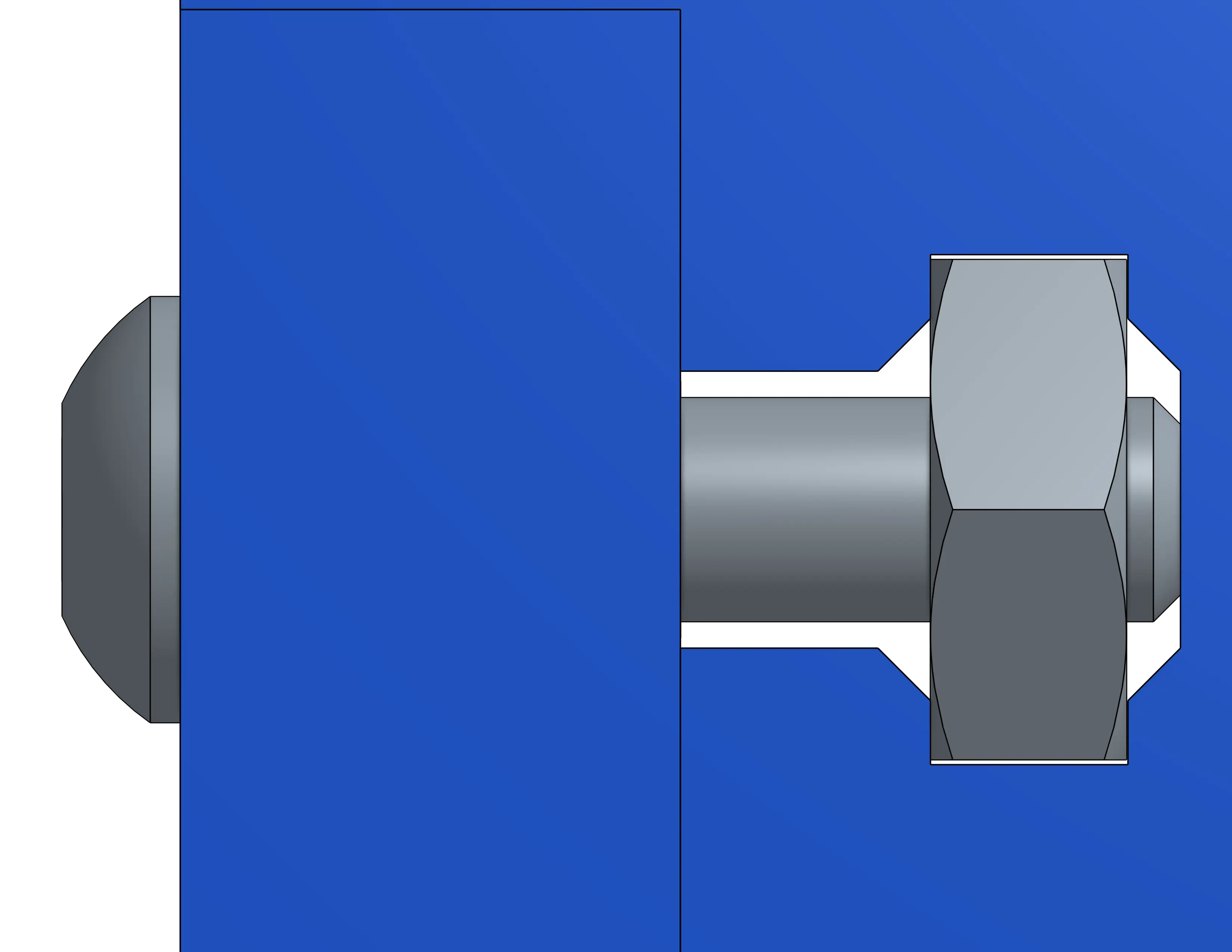

A captive nut is simply a nut held in place by the part itself. This simplifies assembly by removing the need to hold the nut using another method. This method of fastening is similar to tapping the side of a plate, but simpler to execute.

Why use Captive Nuts?

Captive nuts are great for hobby projects because it doesn't add any production cost to your parts. By simply adding the features to your existing plates, you are able to fasten them together. No need to pay for tapping, bending, or PEM hardware. For larger production runs, captive nuts might not be ideal, due to a captive nut assembly likely taking longer to assemble than something made with PEM hardware, or bent.

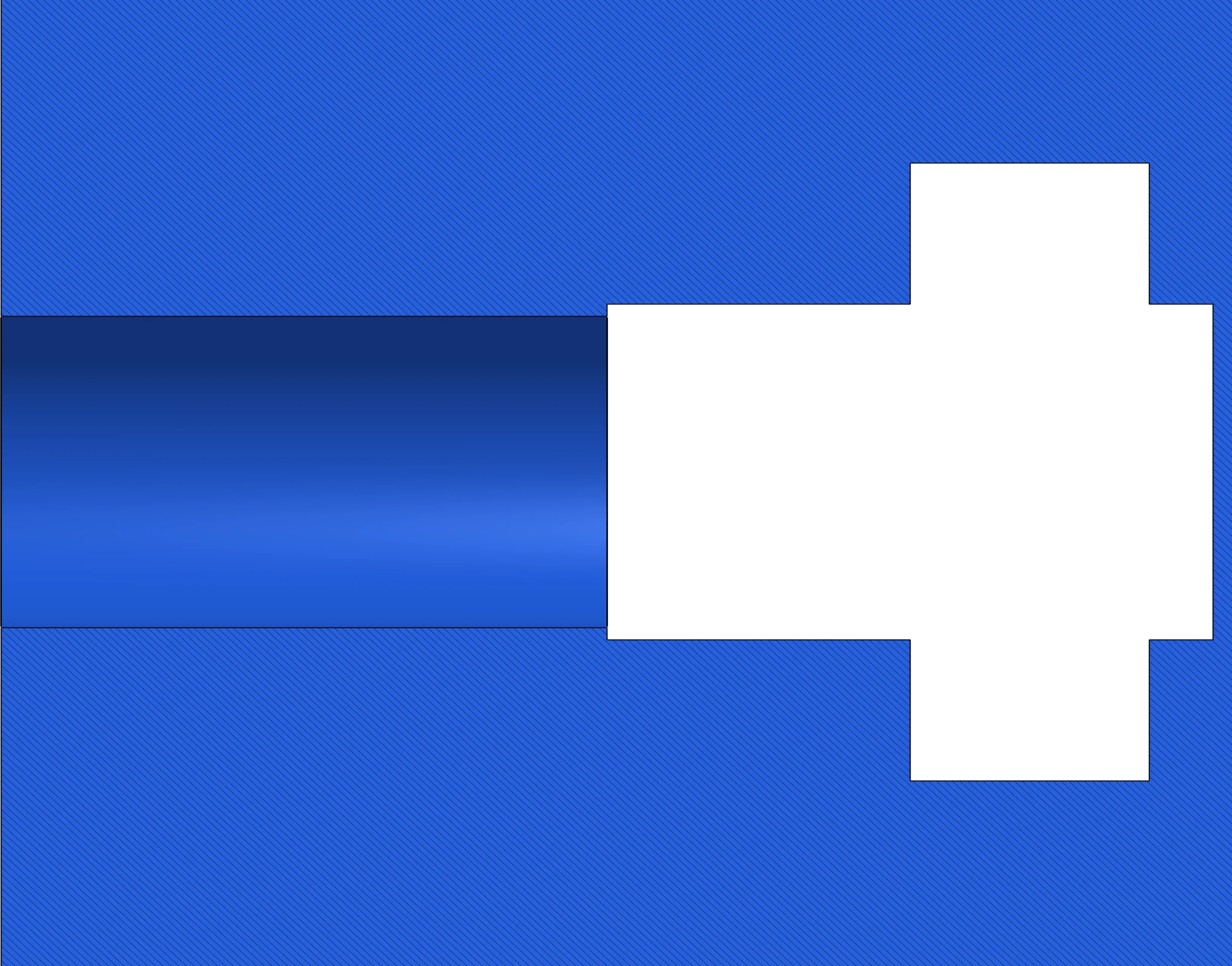

How to design for Captive Nuts

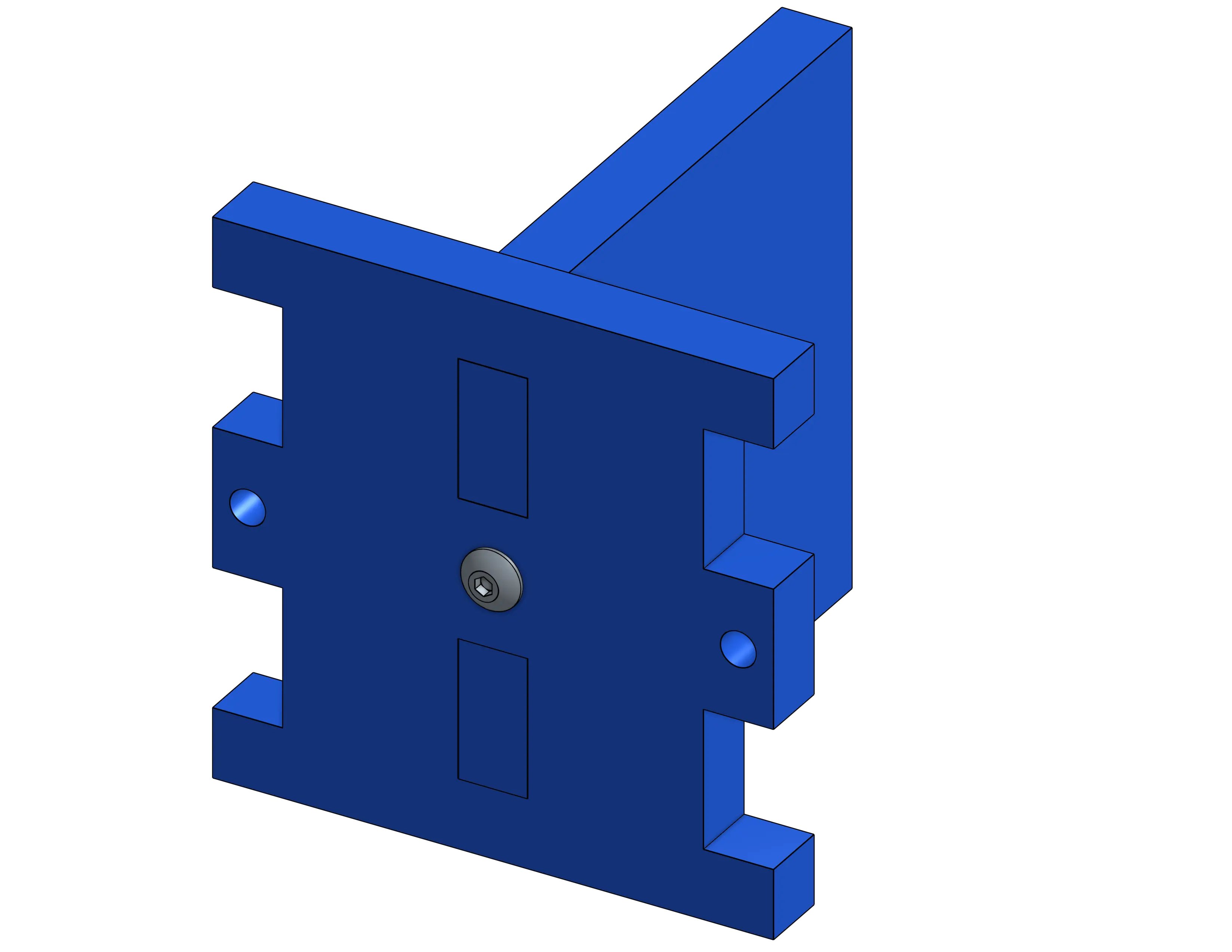

Captive nuts are super easy to design, you just need a simple slot through your part for the bolt to go through and a square hole to fit the nut. It is very important to tolerance your features, to properly fit the hardware you are using. We recommend an overall add of 0.01" for 1/4" material and 0.005" for 1/8" material, to ensure your parts fit together properly when using the Fabworks Laser Cutting Service

While not strictly required, we recommend adding box joints to your captive nut designs to increase the strength of the connection, especially when this connection is not on the edge of a part. This can also during assembly, and reduces the number of fasteners needed to fully constrain the part.

Summary

Captive nuts offer a simple and cost-effective method for assembling laser cut sheet metal parts, especially for hobby projects and prototypes. Key points to remember:

- Captive nuts are nuts held in place by the part itself, simplifying assembly

- Best suited for thicker materials (1/8" or greater)

- Advantages include low cost, easy design, and no need for special tools or processes

- Proper tolerancing is crucial for a good fit (add 0.01" for 1/4" material, 0.0075" for 1/8" material)

- Consider adding box joints to increase connection strength and simplify assembly

- While great for small-scale projects, may not be ideal for large production runs due to assembly time

By incorporating captive nuts into your designs, you can create sturdy, easy-to-assemble sheet metal parts without the need for additional fabrication processes. This method is particularly well-suited for projects where simplicity and cost-effectiveness are priorities.

Laser Cut Text Signs: A Beginner's Guide

Create custom laser cut text signs with this easy guide. Learn to design, model, and produce personalized signs using free software and professional laser cutting services.

Optimizing the cost of Laser Cut Parts

Learn essential strategies for optimizing manufacturing parts to reduce costs.

Order Sheet Metal Parts .

Upload your STEP file for an instant laser cutting quote. Quote in seconds, order in minutes, receive parts in days.

or drag and drop

.STEP / .STP up to 25MB

Your file are safe, secure and retain all intellectual rights.