Everything to Consider when Designing Sheet Metal Parts

Sheet metal bending is a fundamental process in the manufacturing industry, used to create various components and products across numerous sectors, from automotive to aerospace, electronics, and architecture. While the physical act of bending sheet metal involves machines, tools, and technical expertise, the design process is equally critical. Proper planning, understanding of material properties, and meticulous design are key to ensuring quality, efficiency, and functionality in the final product.

In this guide, we will explore the essential techniques, tips, and best practices for sheet metal bending, with a strong focus on the design process. By following these guidelines, designers can ensure their creations are not only manufacturable but also optimized for performance and cost-effectiveness.

Understanding Material Properties

Before starting the design process, it's crucial to understand the material properties of the sheet metal you're working with. Different materials have unique characteristics that affect how they bend, including:

- Ductility: The ability of the material to deform without fracturing.

- Tensile Strength: The maximum stress the material can withstand while being stretched or pulled before breaking.

- Bend Radius: The minimum radius you can bend the material without causing damage.

- Thickness: The gauge or thickness of the sheet metal, which directly impacts the bending force required.

Always consider the material's bendability and thickness when designing. Thicker materials may require larger bend radii and more force, while highly ductile materials can handle tighter bends.

Bend Allowance and Bend Deduction

Bend allowance and bend deduction are critical concepts in sheet metal design that help determine the precise dimensions of the part after bending.

- Bend Allowance: The length of the neutral axis between the bend lines. This accounts for the material stretching during the bending process.

- Bend Deduction: The difference between the initial flat length and the final length after bending. It helps to calculate the required blank size.

Minimum Bend Radius

The minimum bend radius is the smallest possible radius you can apply to a bend without causing cracking or material failure. This value depends on both the material and its thickness. Always adhere to the recommended minimum bend radius for your material. Designing bends with smaller radii than the material can handle may result in cracks, weak points, or even failure during the manufacturing process.

K-Factor and Bend Relief

The K-Factor is a crucial variable in sheet metal bending design that defines the ratio of the material's neutral axis to the thickness of the sheet. It affects the bend allowance and overall accuracy of the design.

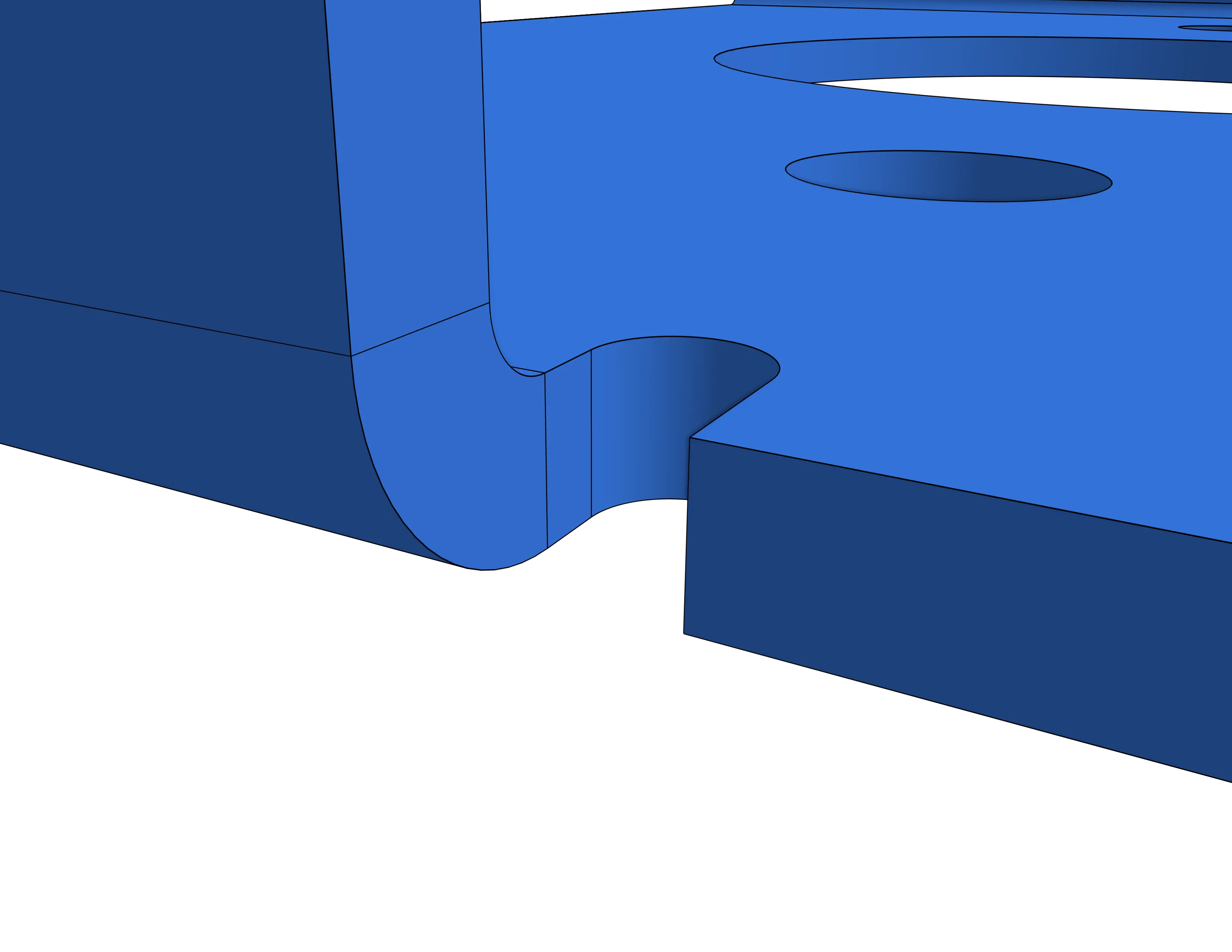

Bend Relief: This is an additional feature added to the design to prevent tearing or deformation near the bend area. It’s especially important when the bend is close to edges or other bends.

Incorporate bend reliefs into your designs wherever necessary, particularly in complex parts. The K-Factor should be calculated based on material type, thickness, and bend angle to improve accuracy.

Bending Sequence and Tolerances

The order in which bends are performed (bending sequence) can greatly affect the manufacturability and accuracy of the final part. Improper sequencing can lead to distortion, misalignment, or even part failure.

Tolerances: During the design phase, it's important to define acceptable tolerances for bends, ensuring that deviations from the intended design are within permissible limits. When using the Fabworks Bending Service please refer to the Bending Guidelines for tolerance information.

Avoiding Common Design Pitfalls

- Over-Complicating Designs: Complex designs with excessive bends, tight tolerances, or unnecessary features can increase costs and reduce manufacturability. Simplifying designs where possible can lead to more efficient production.

- Insufficient Edge Distances: Placing bends too close to edges or holes can weaken the part and lead to deformation.

Leveraging Design Software

Modern CAD (Computer-Aided Design) software offers powerful tools for designing sheet metal parts. These tools can automatically calculate bend allowances, simulate bending processes, and detect potential issues before production begins. Invest time in learning and utilizing sheet metal-specific features in your CAD software. Many programs offer libraries of materials, pre-set bend radii, and automated flattening tools that can save time and improve design accuracy.

Collaboration with Manufacturers

Designing for manufacturability (DFM) is a critical consideration in sheet metal bending. Collaborating closely with your manufacturing partners can help ensure that your design is feasible, cost-effective, and optimized for their equipment and processes. If you are looking to manufacture your part with us don't hesitate to reach out to our support team if you have manufacturability concerns.

Prototyping and Testing

Before committing to full-scale production, prototyping is essential. Building and testing a prototype allows you to identify and address any design flaws, ensure that the part performs as expected, and make any necessary adjustments. Include prototyping in your design timeline and budget. Testing your design in real-world conditions can prevent costly revisions and ensure the final product meets all requirements.

Sheet Metal Bending with Fabworks

At Fabworks, we specialize in precision sheet metal bending services that meet the diverse needs of industries ranging from automotive to electronics and beyond. Our state-of-the-art equipment and experienced technicians ensure that every part we produce meets the highest standards of quality and accuracy.

Lots of the design considerations can be simplified by referencing Fabworks' Bending Guidelines instead of doing complex material analysis. For example bend radius is standardized, and the distortion zone for various materials and thicknesses are listed for you.

Summary

Sheet metal bending is a complex process that requires careful planning and consideration, especially during the design phase. By understanding material properties, calculating accurate bend allowances, and collaborating with manufacturers, designers can create high-quality, manufacturable parts. Avoiding common design pitfalls and leveraging modern software tools will further enhance your designs, ensuring they meet performance, cost, and manufacturing goals.

Whether you're designing for automotive, aerospace, electronics, or any other industry, following these best practices will help you achieve success in your sheet metal bending projects.

Hand Bending Guide

Master hand bending sheet metal parts with our concise guide. Learn essential design tools and techniques for crafting custom bent sheet metal components without machinery.

What is the Distortion Zone?

Learn about the sheet metal bending distortion zone, how to account for it, and how to manipulate it.

Order Sheet Metal Parts .

Upload your STEP file for an instant laser cutting quote. Quote in seconds, order in minutes, receive parts in days.

or drag and drop

.STEP / .STP up to 25MB

Your file are safe, secure and retain all intellectual rights.